Likarolo tse nepahetseng tse phahameng bakeng sa hlobo ea die cast le hlobo ea ente

Mehleng ea kajeno ea tlhahiso, ho nepahala ke morena.Katleho ea ts'ebetso leha e le efe ea tlhahiso e itšetlehile ka boleng le ho nepahala ha likarolo tsa eona.Bakeng sa ba indastering ea ho etsa li-die-casting le ente, likarolo tse nepahetseng haholo li bohlokoa ho netefatsa sehlahisoa se se nang sekoli.Haeba u le khoebong ea ho etsa liforomo tse phahameng, u lokela ho tseba hore likarolo tsa hau li fihlile mosebetsing.Ka lehlohonolo, ho na le tharollo bakeng sa hau feela.

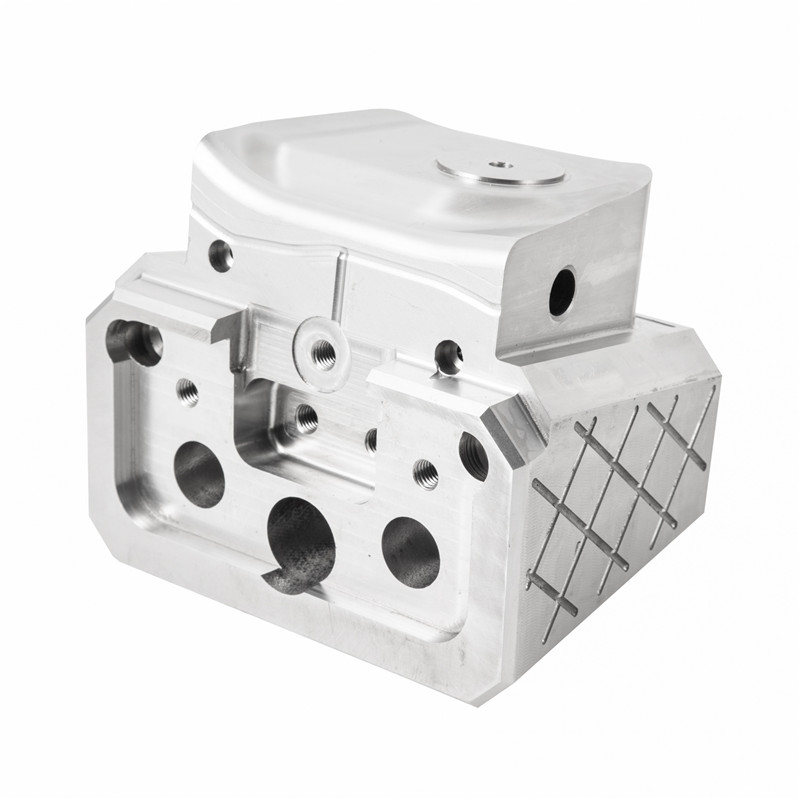

Khamphani ea rona e motlotlo ho fana ka mohala o felletseng oa likarolo tse nepahetseng tse holimo tse etselitsoeng ho lahla le ho bopa ente.Mokhoa oa rona o bonolo;re ikitlaelletsa ho fana ka ho nepahala le ho nepahala, ho sa tsotelehe boholo kapa ho rarahana ha morero oa hau.Likarolo tsa rona li entsoe ka thepa ea boleng bo holimo e netefatsang nako e telele le ts'ebetso.Re utloisisa bohlokoa ba ho kopana le linako le ho fana ka liphetho tsa boleng bo holimo, ke ka lebaka leo lihlahisoa tsa rona li etselitsoeng ho mamella mekhoa e boima haholo ea tlhahiso.

Likarolo tsa rona tse nepahetseng tse phahameng li kenyelletsa ntho e 'ngoe le e' ngoe ho tloha ho li-ejector pins le sockets ho ea ho core pins, sprue bushings le ntho e 'ngoe le e 'ngoe eo u ka e hlokang.Sehlahisoa se seng le se seng sa rona se etselitsoe ho kopana kapa ho feta maemo a indasteri, kahoo o ka ba le ts'epo ts'ebetsong ea bona le ts'epahalong ea bona.Re fana ka mefuta e fapaneng ea libopeho le boholo ho lumellana le tlhophiso efe kapa efe ea hlobo, 'me sehlopha sa rona sa litsebi se letsetsa ho u thusa ho fumana karolo e nepahetseng bakeng sa litlhoko tsa hau tse ikhethileng.

Lihlahisoa tsa rona li pharalletse, empa tse ling tse hlahelletseng moleng oa lihlahisoa tsa rona li kenyelletsa lithapo le li-sockets tse entsoeng ka mochini.Likarolo tsena ke tse ling tsa lintlha tsa bohlokoa ka ho fetesisa liforong tsa lefu le liente, 'me likarolo tsa rona li etselitsoe ho fana ka nako e telele le ho nepahala.Li hahiloe ka thepa ea boemo bo holimo joalo ka tšepe e sa hloekang, tšepe ea sesebelisoa le tungsten carbide, e leng se etsang hore e be e 'ngoe ea likarolo tse sebetsang hantle 'marakeng.

Sehlahisoa se seng sa bohlokoa lethathamong la rona ke Precision Core Pins, tse fumanehang ka mefuta e tloaelehileng le e tloaelehileng.Li entsoe ka mamello e thata ka ho fetisisa 'me re fana ka mefuta e mengata ea ho qeta ho lumellana le litlhoko tsa hau tse khethehileng.Lithapa tsa rona tsa mantlha tse nepahetseng li khona ho sebetsana le liforomo tse rarahaneng haholo 'me li loketse lits'ebetso tse hlokang likarolo tse haufi tsa mamello.

Kenyelletso ea Sehlahisoa

Lintho tse bonahalang/Tšepe:

Kunshan BCTM e ka fana ka thepa ea lehae e theko e boima haholo ka ts'ebetso e ntle haholo, e fumaneng kananelo ea bareki ba rona kaofela.Hape re ka fana ka tšepe e tsoang linaheng tse ling ho tsoa lihlahisoa tse fapaneng lefatšeng ka bophara, joalo ka ASSAB, Schmiedewerke Gröditz, Hitachi Metals, Schmolz+Bickenbach, Finkl Steel, Scana, Crucible, Posco, Doosan, Daido Steel, Koshuha Steel, Sanyo Steel, Nachi , Sinto, Saarstahl, Buderus, Kind & Co, Aubertduval, Erasteel, Sorel forge, joalo-joalo.

Tlhahiso:

Re na le mechine ea maemo a lefats'e ea ho etsa ho sila, ho sila, CNC machining, EDM, ho seha terata, ho sila ka lebelo le phahameng, joalo-joalo Boleng ba rona bo botle haholo ebile bo tsitsitse.Ntle le mechini ea morao-rao, re na le sehlopha sa theknoloji se nang le boiphihlelo le sehlopha sa tlhahiso.Kaofela ha bona ba na le bonyane lilemo tse 18 tsa boiphihlelo ba ho sebetsa.Ba ka fumana litlhoko tsa bareki kapele le ka mokhoa o hlakileng.Boiphihlelo ba bona bo ruileng bo ka thusa moreki ho fumana boleng bo botle bo tsitsitseng mme ba hapile kananelo ho tsoa ho bareki ba rona.

Mefuta ea tlhahiso:

Lisebelisoa tsa CNC: Lebelo le phahameng la CNC e otlolohileng M/C's.

Sink EDM's.

Li-EDM tsa terata.

Lisebelisoa tse fapaneng tsa mochini oa matsoho.

Lisebelisoa tsa CNC.

Mohatelli oa Spotting.

Lisila ka holim'a metsi.

Re sebelisa bonolo

UG, AUTO CAD

Moqapi oa Lisebelisoa

Kunshan BCTM Co., Ltd. e sebelisa mekhoa e mengata e fapaneng ea meralo ea lisebelisoa ho kenyelletsa le litsebi tsa rona tsa lisebelisoa, moqapi oa lisebelisoa lelitsebi tsa tšebetso.

• Netefatso ea moralo oa lisebelisoa ho sebelisa software ea ketsiso ea Mold ho tlatsa lefu, karolo ea thermos le tlhahlobo ea FEA.

• Khutlisetsa morao boenjiniere ba lisebelisoa ho theha moralo ka mokhoa o tiileng.

• CAD: Unigraphics, AutoCad, Mold flow software.

Tlhahlobo

Lisebelisoa tsa boleng

Coordinate Measuring Machine e nang le CAD interface.

Shadowgraph.

Mohlahlobi oa boima.

Plug le Thread gauges.

Ts'ebetsong ea Tsamaiso ea Boleng

• Ts'ebetsong ea Tsamaiso ea Boleng, ho kenyeletsoa ISO 9001\2005 e ngotseng Bukana ea Boleng, Mekhoa le Litaelo tsa Mosebetsi.

• Tsamaiso ea Morero ka litlhoko tsa Bareki.

• Fana ka litlaleho tsa dimensional joalokaha ho hlokoa ke Bareki.

• Fana ka litifikeiti tsa Material kamoo ho hlokoang ke Bareki.

• Ts'ebetsong le tlhahlobo ea ho qetela pele ho paka le ho romelloa.

Ha thepa e fihla fekthering, re tla hlahloba ho thatafala, ho lemoha mefokolo, boholo le lintho tse ling ho netefatsa hore tsohle li nepahetse.Re kenya tšebetsong tlhahlobo ea ts'ebetso ho leka ho fumana litaba kapele kamoo ho ka khonehang ho boloka nako le ho qoba tahlehelo e kholo ea litšenyehelo.Kamora hore tlhahiso e felile, re tla fana ka tlaleho ea CMM.